By Jennifer Elting

Everybody’s out there looking for pennies: Fuel customers are using mobile apps and will make challenging left turns for the promise of saving just a few pennies on a fill-up. Amid this, fuel retailers look for ways to wring a few pennies of profit from the sale. It’s a game won or lost on small increments, and folks on both sides of the counter know that those pennies add up.

In the past few years, discovering the “sweet spot” that brings customers off the street and grows fuel sale volume and profit has become easier. OPIS- and PDI-integrated tools let everybody from single-store operators to chains with hundreds of locations quickly access real-time competitive data. With a click, they can know which stores or regions are underperforming. They can easily see where they’re making the most or least money and where their pricing is getting beat by competitors down the street or miles away.

Real-time insight into volume, margin, and gallon performance gives leaders the ammunition they need to formulate an agile pricing strategy—on a laptop, tablet, or smartphone. But that’s only half the battle. That price now has to go to every POS, pump, and sign in every store. And the longer it takes the more money you lose.

Price Optimization, Meet Price Automation

Imagine this scenario: Based on data that you’ve gathered over several hours, you determine that the price of unleaded gasoline needs to be adjusted by 3 cents in your TX region, which has 12 stores. That information goes out to each store by email, phone, or fax depending on the individual store setup.

Now that each store manager has their pricing directive, the POS system, pumps, and price signs have to be manually updated at each location to reflect the new price. At this point, your pricing “sweet spot” and best opportunity for profit on fuel sales are in the hands of 12 separate store managers.

Why isn’t this scenario giving you maximum results? For starters, you’re spending too much time gathering data that could be at your fingertips. And many times the information, such as competitor surveys, is outdated because the store manager hasn’t had time to send over today’s survey results. Next you’re spending hours sending out prices and then researching each store to see if they made the price change. Not to mention, the store managers are spending unnecessary time away from customers to update price signs outside the store. It could be worse, like if you had to roll out that price at 50 stores? 200? That’s that many more managers who have to intervene personally to make the price change. And that creates many more opportunities for mistakes.

The variables compound quickly: Since regulations require that stores cannot advertise a price that is less than the charged price, getting prices out in the wrong order means regulatory exposure and possible fines. Having managers going up and down ladders or simply stepping outside the store to change price signs not only increases the chance for on-the-job injuries, it takes time away from customer care. And then there’s the “fat finger” syndrome: a store manager keys in a number incorrectly on the POS. This can be an expensive mistake if, say, a store manager types in “1.10” instead of “$4.10.” (True story.) Until you’ve noticed the lines of bargain-seekers at your pump and corrected the mistake, you’re destroying your fuel margins.

And at the end of the day, what assurance do you have that the price has been updated uniformly across all displays and devices, at all locations? That requires another wave of back-and-forth communication between HQ and stores. Without price automation to go with that up-to-the-minute data, your chances for maximum profit are hostage to a chain of dependencies and manual intervention that is entirely unnecessary.

Winning Practices

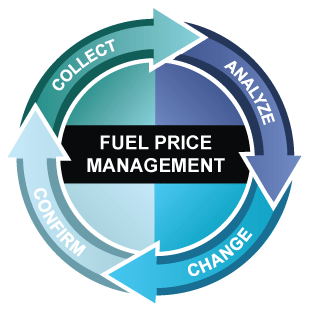

Profit winners have automated the three major components of the process: competitive data collection, analysis, and price implementation.

This means your store managers can spend more time on customer care and other critical operations, while fuel managers are able to see and implement the price that draws the customer off the street and to the pump. Stores that had dial-up modems (if they were connected to the Internet at all) 10 years ago are now agile pricing operations able to get the most from every fuel sale by optimizing and synchronizing execution of one-click fuel prices to the POS, pumps, and electronic price signs.

A C-Store Chain Finds Six Figures of Savings

Altoona, Pennsylvania-based Sheetz convenience stores, founded in 1952, have now grown to more than 437 locations across six U.S. states. Their director of store support was exploring ways to reduce the cost of store service calls, reduce store-level pricing errors, and execution delays while helping their store managers spend more time with their customers.

As part of a pilot program, they implemented a solution that let them manage electronic price signs from headquarters or in-store rather than at the sign and remotely reset electronic price signs from a central location.

These two improvements translated into forecasted annual savings of $141,000 in service maintenance, and increased available store manager face time with customers by up to 50 hours annually per store—across 360 stores. Sheetz also realized these additional benefits:

- A 49% reduction in onsite service calls through conducting remote reset of price signs

- The ability to instantly react to competitive market changes, thereby maximizing revenue opportunities

- The ability to proactively head off potential problems with remote monitoring and dynamic notification of pricing errors

- Lower total service costs

- A reduction in system downtime, inaccurate price changes, and amount of time to make price changes

- The elimination of the need to consider updating or replacing existing equipment, which could cost in the tens of thousands annually

- Happier, more productive store managers who had more time to do what they do best — manage their stores

The profit winners in today’s battle for the pump dollar set themselves up to win by:

- Leveraging tools to give them real-time data that help them set the best price

- Centralizing and automating updates to make sure the best price is instantly on display on every sign, at every store.

Knowing the best price is one thing. Being able to act on it is another.

Jennifer Elting is director of marketing for Skyline Products. Jennifer has been a marketing professional in the c-store industry for more than 10 years and holds a Bachelor of Administration degree in Marketing from the University of North Texas.

Skyline Products has been designing and manufacturing signs for safe highway notifications and accurate fuel pricing since 1970. They are the industry-leading manufacturer of state-of-the-art electronic sign solutions and price management software for the retail fuels industry and ITS-grade dynamic message signs and central control software for transportation management applications and vertical government segments in North America.