Husky Corporation now offers EagleFlex Low Permeation Hardwall Gasoline Pump Hose, which reduces the diffusion of fuel through the hose wall. A number of states now require gasoline dispensing facilities to install low permeation hose, often in decommissioning of their Stage II vapor recovery system regulations or as an added measure to control air pollution.

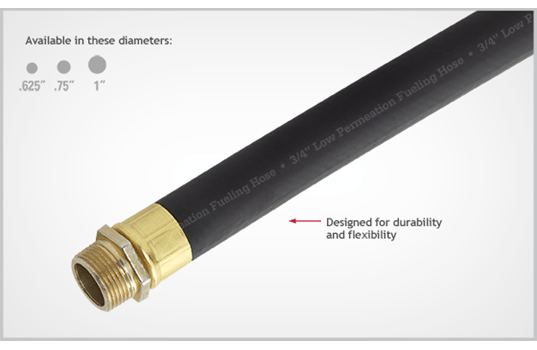

EagleFlex Low Perm Hose meets UL 330 requirements for fuel hoses designated as low permeation for fuel loss through the flexible hose, at the fittings and at the connection between the hose assembly and the dispensing equipment at a rate no more than ten grams per square meter per day. The hose is made of black Chlorinated Polyethylene (CPE), reinforced by multiple textile braids with dual static wire helix, and features permanent external crimp zinc-plated steel couplings and/or swivels.

“This low perm pump hose is recommended for a variety of applications where hardwall fuel hose is needed. It is appropriate for many fueling applications including unleaded or leaded gasoline, gasohol blends, E-15 Ethanol, diesel and B-20 Biodiesel,” said Brian Wolff, Husky Corporation Project/Design Engineer.

State Regulations Increasingly Require Low Permeation Fuel Hose

Several states currently require or are considering a mandate for low permeation fuel hose as an additional step to control air pollution. For example Ohio now requires gasoline dispensing facilities to install low permeation hose, which the state estimates will reduce VOC emissions by approximately 10.8 pounds per hose per year.

Contact Husky Corporation today to learn more about the durability, flexibility, and other benefits of EagleFlex Low Permeation Hardwall Gasoline Pump Hose at 800-325-3558 or [email protected].