Using Life Cycle Analysis to Reduce Emissions and Expenses

By John Eichberger

Life cycle assessments (LCA) are among the most important—yet least understood—ways to determine how to examine carbon emissions and set policy related to these emissions.

This general lack of awareness is why the Transportation Energy Institute (TEI) published the white paper, “Using Life Cycle Assessment to Evaluate the Light Duty Vehicle Transportation Sector” in March 2025.

In simple terms, a life cycle assessment looks at all the carbon generated from the furthest upstream elements of producing the fuel or electricity. Other approaches simply look at the carbon emitted at the tailpipe. Of course, with electric vehicles (EVs) there is no tailpipe on the car, but there are very large “tailpipes” at the electric powerplant. Those emissions need to be considered if carbon reduction is a serious goal.

The TEI white paper argues that using LCA can help identify the most efficient means for reducing emissions, which can result in economically sustainable investments, achieving reductions that make financial sense and will therefore continue to provide meaningful environmental improvement in the long term.

To provide context, let’s look at the comparative analysis TEI published in 2022 that examined life cycle emissions of three small sport utility vehicles with different powertrains: internal combustion engine (ICE), hybrid electric vehicle (HEV) and battery electric vehicle (BEV).

A key finding was that approximately three-quarters of emissions over a vehicle’s 200,000-mile expected lifetime comes from the energy it consumes, whether that is liquid fuel or electricity. Because vehicles consuming liquid fuels will dominate the roads for decades to come, the greatest benefit to the environment will be achieved by reducing the carbon intensity of both fuel and electricity.

Decarbonizing Fuel

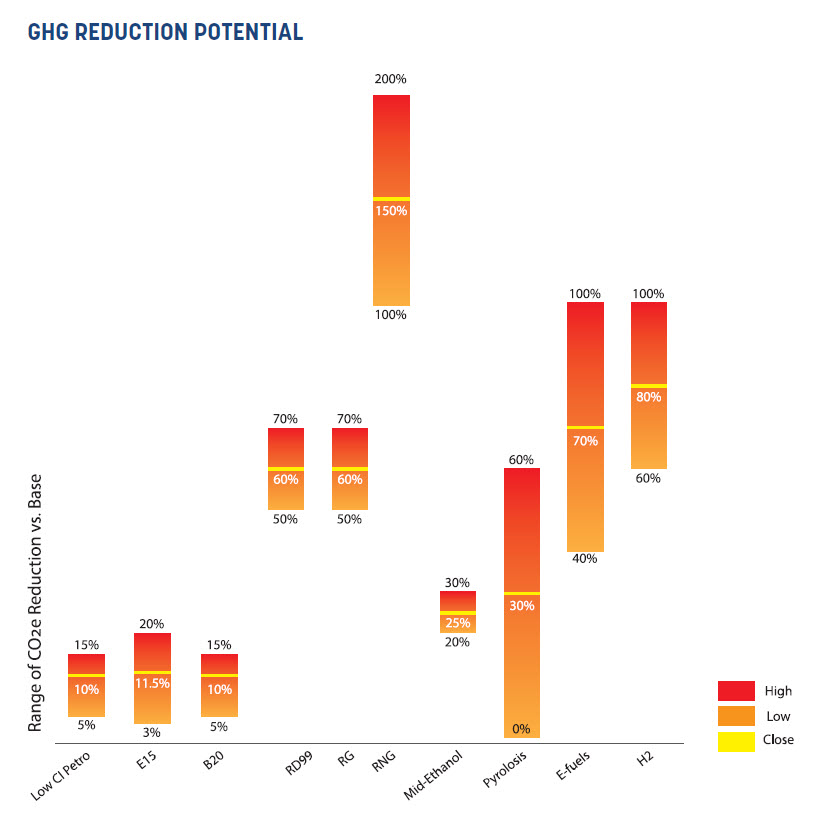

So how do you get the carbon out of fuel? TEI has published several studies that look at options to reduce the overall carbon intensity of liquid fuels. These options include bio and renewable fuels, e-fuels, various blends of low-carbon fuels and conventional petroleum fuels in addition to the growth of options like hydrogen. Many of these options would not only reduce emissions but could also contribute to more efficient production methods and, depending on cost, improved financial returns. They offer an opportunity to simultaneously benefit the environment and fuel producers.

For example, the life cycle carbon reduction potential for blending ethanol and biodiesel results in carbon reductions of 6% with E10 (10% ethanol) to 50.8% with E85 (85% ethanol) and 56.8% with 100% ethanol. These values are national averages. Biofuels from feedstocks that were produced using advanced agricultural practices could yield even lower carbon intensity values. To better understand this opportunity, TEI has organized a Sustainable Agriculture Working Group to help standardize agricultural practices that could contribute to lower carbon intense biofuels.

Optimizing Carbon Reduction

Without looking at carbon from a life cycle standpoint the carbon inputs from electrical production are overlooked. On average, U.S. power plants emit 794 pounds of CO2 for every megawatt hour of electricity they produce. TEI has not commissioned research into how the carbon intensity of the electricity used to power BEVs could be reduced, but other organizations are examining the issue. It is critical that BEVs are powered by lower emitting electricity.

The bottom line is that by focusing on every part of the life cycle and supply chain, we can identify the best opportunities to reduce emissions, enhance efficiency, remove waste and boost profitability. If we do not think about transportation as a complete system, finding such opportunities may prove elusive.

John Eichberger is the TEI executive director.

John Eichberger is the TEI executive director.